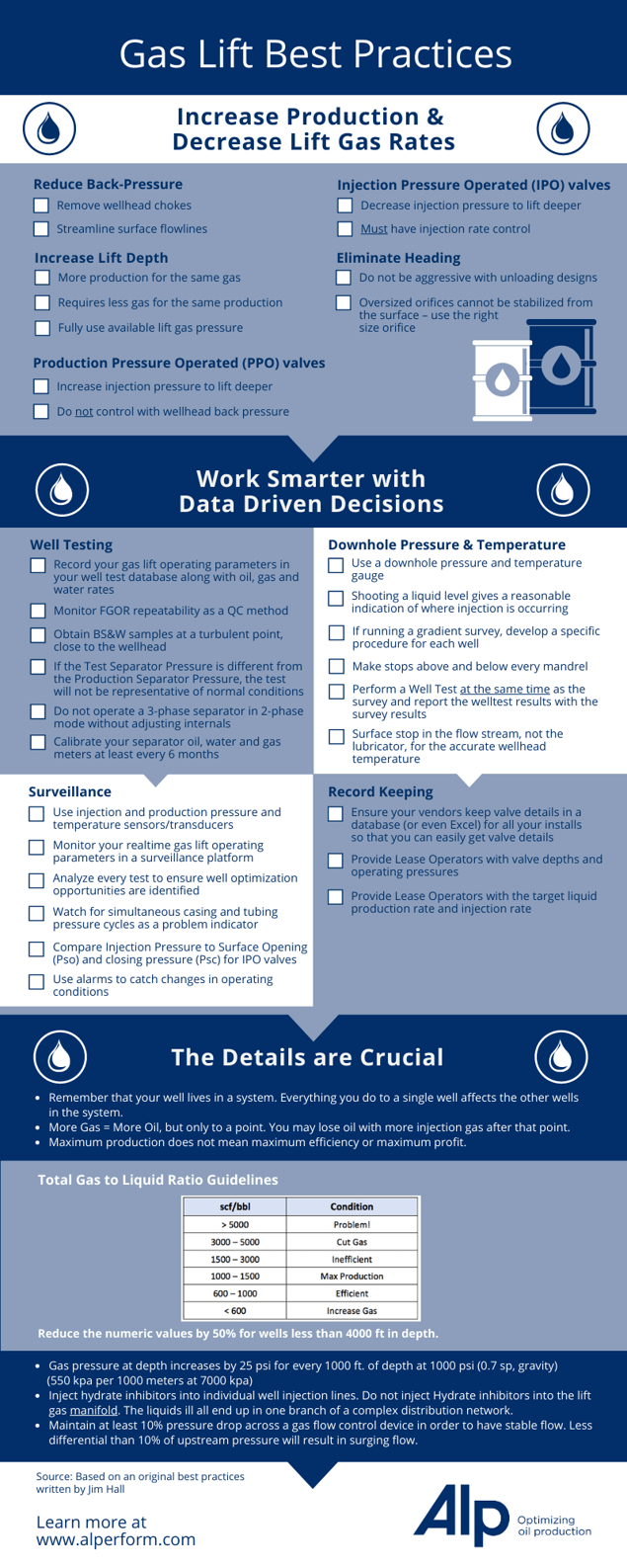

This blog was inspired by a posting by Jim Hall (retired Shell Gaslift SME) on LinkedIn in 2020 where he shared his tally book-sized gas lift best practices. We’ve taken his ideas and given them a little bit of an update for modern technology and tools. We hope you find this useful.

Gas lift is an appropriate and effective lift method for many well types, especially gassy wells. Robust and reliable, gas lift wells continue to produce — even when operating inefficiently. However, this also creates a huge opportunity — if we can diagnose when a gas lift well is being operated sub-optimally then it gives us an opportunity to recover a missing wedge of production. You do not have to let lower production be the norm — using these best practices you can improve the management of your gas lift wells and data to maximize your well production.

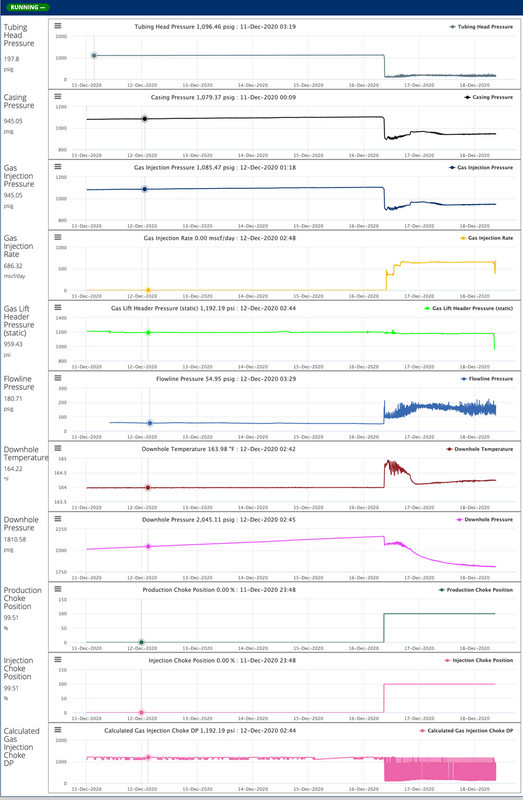

Surveillance is the key to making sure well performance is known and understood. Monitor your realtime gas lift operating parameters in a surveillance platform.

Analyze every test to ensure well optimization opportunities are identified.

Using software like Pump Checkers® gas lift module helps teams to manage more wells in less time, readily identify problems, and address opportunities to increase production.

With the potential to reduce operating expenses, increase base production by 5-10%, and allowing your operators to focus on both potential problems and opportunities to increase profit, PumpChecker pays for itself in days.

Note for Blog Listeners: This blog includes detailed graphs, charts, and visual aides that can be viewed on the ALP blog..jpg?width=2097&height=770&name=ALP%20logo%20%26%20strapline%20-%20RGB%20(US%20version).jpg)

-2.jpg?width=100&height=100&name=ALP%20logo%20%26%20strapline%20-%20RGB%20(US%20version)-2.jpg)