Over the last few blogs we’ve talked a lot about the value of automated processing of realtime data in the oilfield. Today I’d like to ‘land the plane’ a little and make that more tangible for wells produced using gaslift…as well as make this a quick read.

Gaslift is being used extensively throughout the Permian (and on some Bakken wells) to produce unconventionals. Gaslift is a reliable and robust artificial lift method but requires careful and continuous monitoring to ensure that optimum oil production is achieved.

Common Gaslift Well Problems Include:

Too Many Mandrels

- For a well at 10,000ft we recommend 9 valves, many times we see 14 - 15 valves which results in never being able to inject at the orifice. Why pay for more valves/mandrels than you need?

- There is a casing pressure drop every valve (25 psi), which results in insufficient pressure to be able to inject at depth. A lose-lose scenario.

Injecting Shallow

- If gas is being injected consistently at shallow valves, drawdown is reduced, and production will be lower.

- Gaslift design requires accurate knowledge of well flowing temperature, if the temperature used in the design is incorrect this can result in incorrect valve actions, reduced drawdown and less production.

- Valve port scaling or blocking results in excessive pressure drop and injection rates will be reduced as well as the ability to transfer to the next valve.

Change in Inflow Performance (Which Always Happens on Unconventionals)

- A reduction in reservoir pressure or decline in well productivity index (e.g. due to scaling at perforations) can severely compromise the operation of a gas-lift well.

- The early detection of this change can assist with well optimization (by changing gas-injection rate or a re-design of the valves) and reservoir performance monitoring.

Artificial Lift – The Panacea

Gaslift is often viewed as a ‘failure free’ way to produce wells using artificial lift. However, it’s far from a trouble-free way of producing your wells.

The decision to use gaslift rather than ESP can be a great choice, especially on high GOR/GLR wells. However, the downside is that drawdown is almost always limited which results in lower production.

If the gaslift system does not function correctly then injection is shallow and production is curtailed, resulting in lost barrels in the tank and lost revenue.

A comprehensive data management and interpretation system is critical to assist with all aspects of gas-lift well performance, otherwise your likely to be losing a wedge of production.

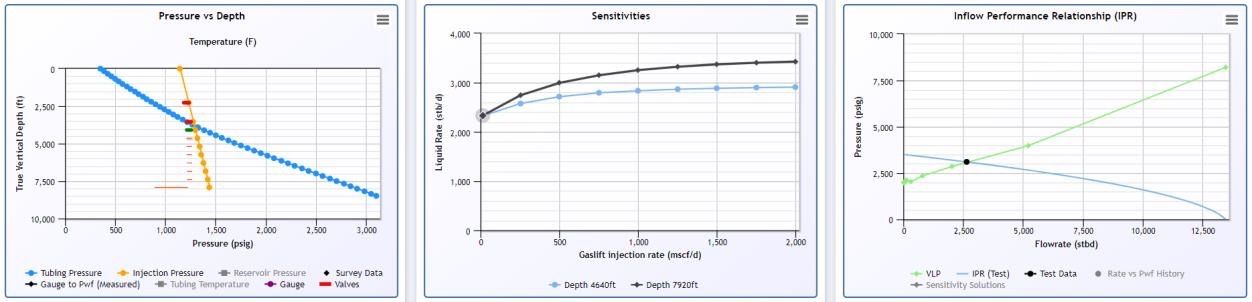

The image below shows a well where injection is shallow and drawdown on the well is low – the operator is losing production.

ALP’s PumpChecker® software can help identify such problems and assist you to maximize your well production.

.jpg?width=2097&height=770&name=ALP%20logo%20%26%20strapline%20-%20RGB%20(US%20version).jpg)