When oil prices are low it’s more important than ever that we optimize the way our wells are produced. How can we “double down” to ensure that our wells are produced efficiently at the lowest cost of operation? This article summarizes how you can do that now and for the long term.

Innovation—Stop Talking and Start Doing

A recent LinkedIn article By Ryan Dawson, CEO of Corva, a company that works with realtime drilling information titled The Oilfield Innovation Model Is Broken states:

“For an industry that talks so much about the “Digital Oilfield,” there was surprisingly little innovation, at least to someone who is used to working with cutting edge tech and companies like Netflix. What I saw was painfully slow, incremental innovation from a few companies. This translated to meager gains in drilling and completion efficiency. The digital transformation happening in many other industries had yet to take hold in oil & gas. Fast forward to today. I can report that the status quo hasn’t changed much. The oil & gas industry appears to be plodding along as usual.”

How do we turn this around? How do we stop plodding, get up and running, shed a few pounds and get healthy as an oil producer?

Digital Strategies—Affordable and Successful

The beautiful truth is that implementing digital oilfield strategies, machine learning, analytics and all the buzz words, can be done at a surprisingly low cost and provide amazing value for your operations. Some of the first areas to get hit in a downturn are digital projects and IT budgets. Should that be the case if you want to thrive?

The Rollercoaster—Boom and Bust

The recent and rapid collapse of oil prices from $50+ to negative oil prices per barrel, caught many operators by surprise and resulted in immediate corporate sphincter-clenching and drastic cost cutting. Many projects have been deferred or cancelled, drilling activity has been cut way back, many operators--as well as large service companies--have laid off thousands of people, resulting in irreplaceable loss of corporate memory.

There is some good news, though. At the time of writing, WTI crude has gone from -$40 to +$40!

Why Act Now? How Long Will Prices Remain Low?

Set against a backdrop of reduced demand due to Covid-19, competition between Saudi Arabia and Russia to maintain market share as well as low demand from China, we wonder what will happen to the oil price? Quite simply, none of us know. But, the likelihood is that low and uncertain oil prices could be with us for a while is pretty high. We need to be prepared to survive in an ongoing low-price environment--for the current time and in the future.

Are We Making the Same Mistakes…Again?

Some of the first areas to get hit in a downturn are digital projects and IT budgets. To cope with lower prices and loss of revenue, oil companies have made huge cuts to capital spending; they're drilling far fewer new holes and pressuring their suppliers to reduce prices to give them relief on costs. At some point the cost cutting reduces their ability to deliver oil and revenues start to fall. So what do we need to do?

Across the oilfield, advances in production technology, increased instrumentation, and the resulting data streams can transform operations and related processes, especially when using artificial lift.

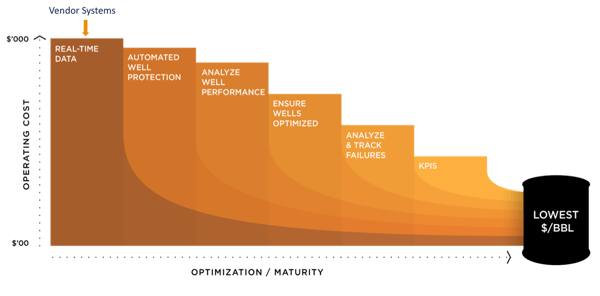

A pressure transmitter is cheap. Transmission of realtime data is inexpensive. Storage of data gets cheaper all the time. There’s really no excuse not to have the data you need to ‘fuel’ expert systems. With this information you can move from the left-hand column of Figure 1 to the right-hand side, reducing Lease Operating Expense (LOE) and achieve lowest total cost of operation.

Figure 1 - Improved maturity of automation reduces LOE

Producers with the ability to act on real-time insight obtained from operational assets have an opportunity for a significant advantage. While the numbers of wells are increasing from tens to thousands, the amount of real time data streaming from the wells and production equipment is exploding. At the same time, there are fewer engineers monitoring the equipment and resource deployment is an increasingly tricky dance.

Bain and Company1 state that:

“Analytic advantages could help oil and gas companies improve production by 6% to 8%.”

And go on to say that companies with better analytics capabilities are:

- twice as likely to be in the top quartile of financial performance in their industry,

- five times more likely to make decisions faster than their peers, and

- three times more likely to execute decisions as planned.

What’s not to like about that? In times like these we need analytics more than ever.

Build or Buy?

We then consider the tricky question of do you build your own or buy it? In a recent blog I explained why digital projects fail and how to make them successful, which provides some key insights on the aspects that need to be considered.

IT people look at an ‘expert system’ and see tables, charts, graphs and dashboards. The immediate response is that they can do that using Power BI. However, they don’t know what needs to be included in a system because they have no domain or subject matter expertise, nor do they understand the complexity of the calculations that go into populating the dashboards. Building expert systems ‘in house’ often ends up costing a whole lot more than buying it, and that’s before you consider the ongoing upkeep and maintenance costs.

Why We Need to Automate!

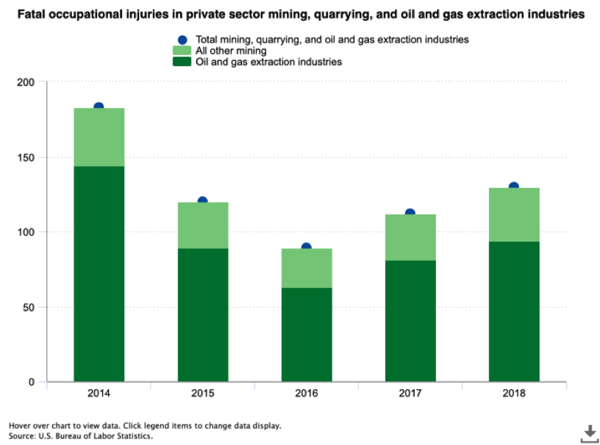

US Bureau of Labor statistics2 show that the oil and gas industry results in 3-4 times as many deaths per year as the mining industry as shown in Figure 2. What’s even more scary is that roughly 4 of every 10 workers killed on the job in this industry, are killed as a result of a highway vehicle incident3. Reducing the time that our workers spend on a daily basis driving to wells should be part of risk minimization strategy for any oil and gas company. Implementing a system that can monitor and optimize your wells in realtime, all remotely, minimizes risk.

Figure 2 - Oil and gas fatalities compared to mining

Most oil companies using artificial lift have vendor provided systems or SCADA systems that do little more than draw line on a screen, while still requiring a lot of human intervention on a daily basis. That’s before a problem has been discovered and there is still the need to do further processing to figure out what is going on!

Industry statistics show that engineering staff spend 28% of their time dealing with email4 and up to half of their days in meetings5. Who has time to look at lines on a screen? That is why it is so important that we have the machines looking at the data, not people. My colleague Shane is a Terminator fan and likes to say “let the machines do the work….”

Figure 3 – Terminator Genisys

As the functionality of your digital capability evolves and your automation maturity or “machine capability” increases, your cost of operation should decrease.

How do you justify it?

In working with our clients, talking about “production optimization” is a bit like “nirvana”; everybody would like it but they don’t know quite how to do it, or can’t figure out how to justify the cost of doing it. And if, like some companies, you’ve cut back so much on staff, you are mostly just fighting fires, with no time to do anything except get failed wells back online.

Based on our experience of working with clients and providing our Pump Checker® software on thousands of wells, we decided to develop a model which helps people understand how to evaluate their performance with respect to how they manage their artificial lift operations and the value associated with improvement. Associated with the model is a financial calculator that quantifies the value associated with performance improvement due to better analytics. Systems like our Pump Checker software provide a double-digit ROI and should pay for themselves in the first month of use.

True Production Optimization

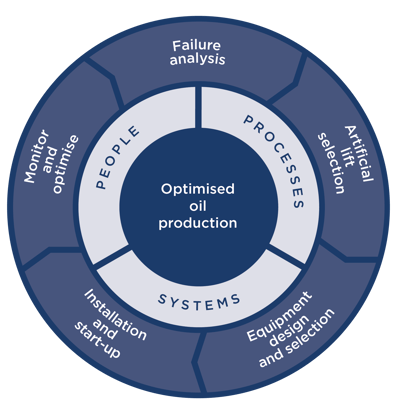

Our True Production Optimization model is based on six pillars of production optimization, as shown in Figure 4. For each of these pillars, we define performance levels, allowing operator personnel to self-evaluate themselves against a performance continuum and define current state vs. future desired state.

Figure 4 - The six pillars of production optimization

Here’s what you need as part of high-level performance on each of these pillars:

- Monitoring: You have a system approach that facilitates integration of realtime data with production and artificial lift equipment data to allow automated performance analysis and identification of problems at all levels.

- Downtime Prevention: You know how much production you lose by well and by cause on a daily, weekly, and monthly basis, and actively work to reduce such downtime through understanding how to mitigate repetitive problems.

- Optimization: You have diagnostic software that automatically analyzes well and AL performance every production and a test that identifies production increase potential through lift parameter changes or proactive workovers to ensure that well production is continuously known and optimized.

- Runlife: You understand artificial lift design and specification at a component level and proactively change and evolve your specifications to improve runlife. You witness equipment assembly and installation to prevent and mitigate problems.

- Proactive Intervention: Operational data allows you to predict impending failure and sub-performing equipment. Based on these indications, you perform proactive workovers to mitigate production loss.

- Cost reduction (lowest total cost of operation): Paying more the first time but getting it “right” reduces cost. You truly understand the effect of downtime events, sub-optimal AL performance and frequent workovers on our total cost of operation. You'll pay for systems and processes to reduce total lift cost.

Pillars 1,2,3 and 5 apply to your existing wells. Pillars 4 and 6 are longer term goals.

In summary, the lowest total cost of operation or lowest $/bbl, requires focus on two things:

- increasing the barrels of oils produced, while

- minimizing the frequency of well intervention

At $30/bbl every 100 barrels of oil that is not produced is $1 million less in revenue, while taking runlife from 8 months to 16 months on your well population saved one client $20 million/year.

A digital solution that can help you realize these gains on your artificial lift wells can be surprisingly inexpensive to license and very quick to implement.

If you’d be interested in evaluating your company operations using our scorecard, please get in touch by filling out the form below.

REFERENCES

- https://www.bain.com/insights/big-data-analytics-in-oil-and-gas/

- https://www.bls.gov/charts/census-of-fatal-occupational-injuries/fatal-occupational-injuries-private-sector-mining.htm

- https://www.osha.gov/SLTC/oilgaswelldrilling/safetyhazards.html

- https://www.mckinsey.com/industries/technology-media-and-telecommunications/our-insights/the-social-economy

- https://www.industryweek.com/innovation/article/22010897/youre-wasting-your-time-and-650-billion-dollars

This article has also been published on LinkedIn.

.jpg?width=2097&height=770&name=ALP%20logo%20%26%20strapline%20-%20RGB%20(US%20version).jpg)