The oilfield has a fabulous opportunity ahead, a truly digital environment for production engineers - but what does that entail?

The recent pandemic has proven to us that digital connectivity keeps our lives and businesses functioning. At the start of the Covid-19 lockdown, one of our clients told us:

“since we’ve been working at home, ALP’s Pump Checker is our only IT system that is working…it’s great that we can still see our wells”

How well prepared are we to truly use technology to improve efficiency in our daily activities using technology?

In his recent article featured by EnergyNow Media, Geoffrey Cann talked about the difference between purchasing digital tools and truly embracing digitalization within the oilfield industry. When looking to take that leap to become a digitally-based organization, many companies consider themselves “digitalized” if they implement a new ‘tool’ to automate some of their processes.

What ALP Learned About Digital—Even Before the Pandemic

Digitalization has been growing, expanding into many industries. Millennials use digital tools as comfortably as older generations used a calculator or a corded phone. The oilfield has been late to the party, many companies believe taking the approach that a few programs used to speed up traditional processes makes them “digital.” But this isn’t BEING digital. There are concrete parts to a digital solution and understanding them will help you and your organization take that leap.

The Digital Trinity

Data. The “lifeblood of digital;” it is the collection and integration of information from multiple sources and systems — operating data and production data. Data is what we are attempting to process with digitalization.

Data. The “lifeblood of digital;” it is the collection and integration of information from multiple sources and systems — operating data and production data. Data is what we are attempting to process with digitalization.

Analytics. To increase productivity and optimize what your company produces, you must analyze the data (see above). Due to the overwhelming amount of data, we need machines to perform the calculations.

Analytics. To increase productivity and optimize what your company produces, you must analyze the data (see above). Due to the overwhelming amount of data, we need machines to perform the calculations.

Connectivity. The network used to allow devices (and the humans which use them) to connect to each other to communicate, share information, and take action. Without action, nothing changes.

Connectivity. The network used to allow devices (and the humans which use them) to connect to each other to communicate, share information, and take action. Without action, nothing changes.

The Framework of Being Digital

Core.The purpose behind being digital is the ability to process the vast (and increasing) amounts of data. Using machines to process the data and connecting humans to utilize it to make decisions faster and more accurately is the heart of being digital.

Core.The purpose behind being digital is the ability to process the vast (and increasing) amounts of data. Using machines to process the data and connecting humans to utilize it to make decisions faster and more accurately is the heart of being digital.

Foundation. The location in which data is stored, the platform (including its ease of use) is the foundation. A good digital foundation is designed to handle innovations as they continue to appear.

Foundation. The location in which data is stored, the platform (including its ease of use) is the foundation. A good digital foundation is designed to handle innovations as they continue to appear.

Capabilities. At the heart of being digital is your company’s plan for implementation and growth. It is important to have a vision, educate and prepare your team, and create a roadmap for digitalization. Finally, raise your data intelligence. Understanding and utilizing data are some of the biggest gains in digitalization, and your team can to be ready for the onslaught.

Capabilities. At the heart of being digital is your company’s plan for implementation and growth. It is important to have a vision, educate and prepare your team, and create a roadmap for digitalization. Finally, raise your data intelligence. Understanding and utilizing data are some of the biggest gains in digitalization, and your team can to be ready for the onslaught.

How You Can ENABLE Being Digital

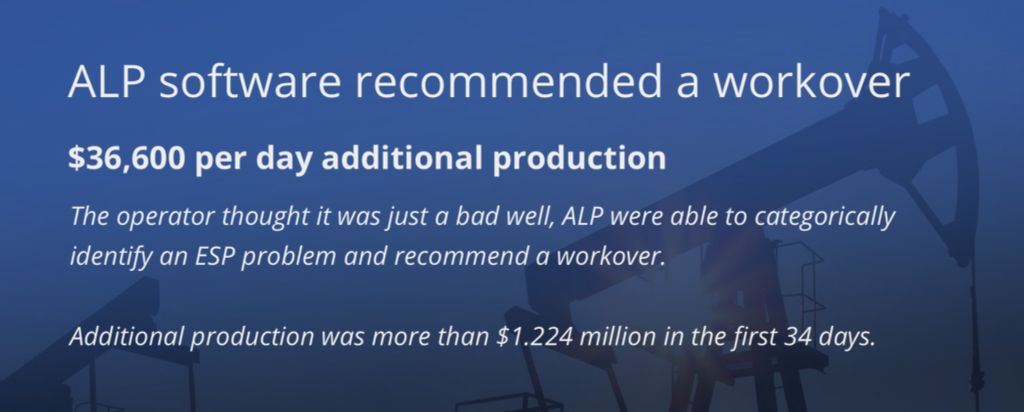

Whether you work in a major oil company with unlimited resources or for a small company where every barrel of oil counts, you probably don’t have the correct tools to integrate your data, analyze well performance automatically and optimize your production. As part of being digital, production engineers need the tools to help them focus on where they can add value (hint – not administrivia) and deliver value for their company. ALP's PumpChecker® software was developed to address this need by providing a platform to deliver analytics and make better decisions.

A Digital Blood Infusion

When you are ready to take the leap to BE digital, change is required and can be uncomfortable, at least initially. But, by diving right in and utilizing the technology available to your team, significant gains are possible. Utilize your younger employees for enabling the change (they have enthusiasm for modern technology), but consult your industry veterans for their input on know-how and best practices.

The benefits to your efficiency, your production, and your image in today’s automated, conservation-minded world, will all get a big boost when your company truly embrace and BECOME digital.

.jpg?width=2097&height=770&name=ALP%20logo%20%26%20strapline%20-%20RGB%20(US%20version).jpg)

-2.jpg?width=100&height=100&name=ALP%20logo%20%26%20strapline%20-%20RGB%20(US%20version)-2.jpg)