This blog will discuss the questions that every unconventional operator wants to have answered, “which artificial lift method should I use?” and “when should I change lift method?”

Is there a right answer? Probably not. But, we will set down some ideas that will help.

Operator Goals

Today’s operators are motivated by different drivers:

- lease operating expense (LOE) vs. capital

- initial production rates vs. reserve recovery

- high initial production rates and cash repayment vs. lower rates with a longer-term potential

but at the end of the day, the lowest total cost of operation is a key goal.

The Rejection of ESPs

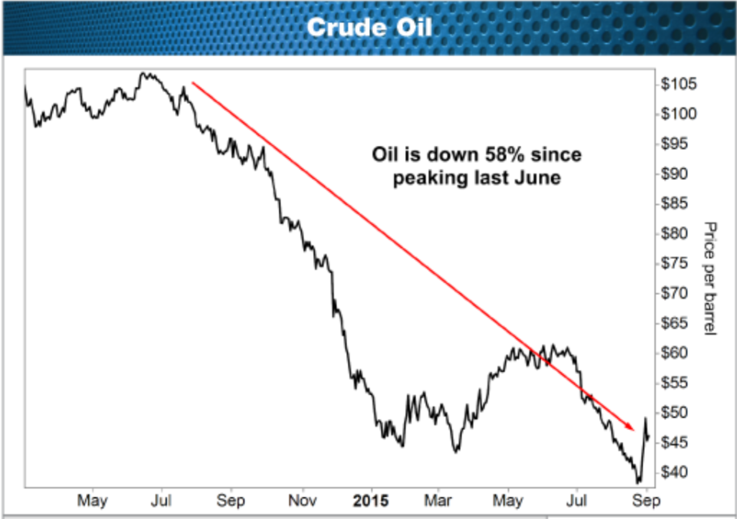

The previous time we had a major drop in oil price in 2014/2015 (Figure 1), many unconventional operators abandoned ESPs; sick of atrocious runlife, they’d had enough and wanted to eliminate repetitive ESP replacement costs. The switch to gaslift was massive.

Figure 1 - Oil price decline

Under a low oil price, gaslift seemed like a more dependable and less costly option. But when oil price crept back up, operators realized that they could not achieve the same high production rates with gaslift, leaving $ in the ground.

A Realization of ESP Value

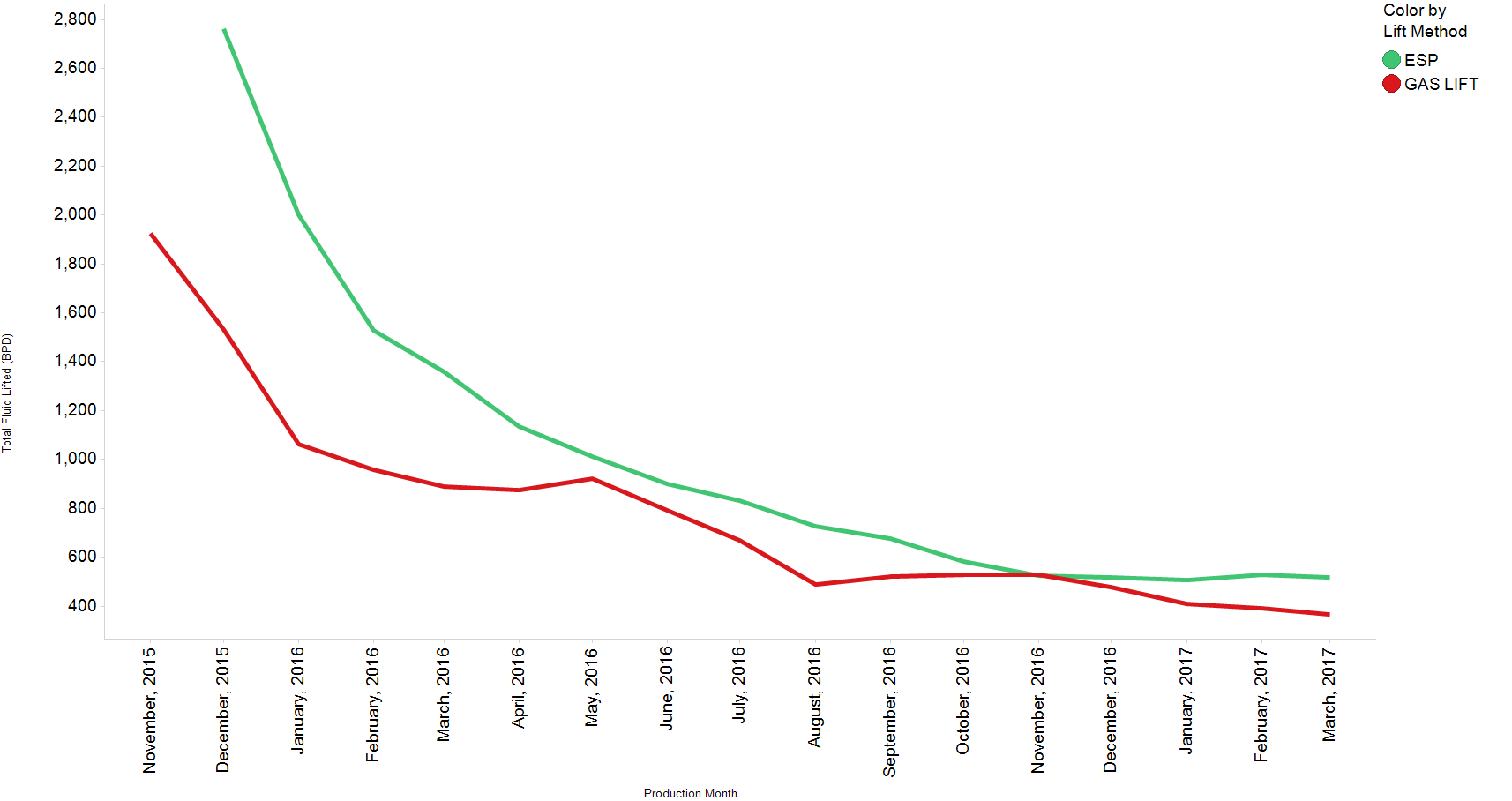

Slowly, operators switched their higher rate wells back to ESP. Figure 2 shows ESP rates vs gaslift rates on comparable wells. At total fluid rates over 1000 bfpd the ESP can achieve higher rates, below this rate there is less of a difference between the lift methods and so gaslift can achieve the required drawdown.

Figure 2 - ESP production rates vs gaslift for comparable wells

By using gaslift on higher rate wells, operators lose a wedge of production. Ultimately, the decision on the correct method comes down to economics, payout and ROI. Most operators that have spent $10 million on a new well want to recover their investment as quickly as possible. Longer laterals and higher initial rates would normally push you to choose ESP as the lift method.

Lift Selection

Appropriate lift method selection is the key to achieving lowest total cost of operation. My 2008 paper, Artificial Lift Optimization in the Orito Field, has more guidelines on how to perform lift selection (or deselection!) and can be downloaded here.

But there are general guidelines that do apply and so here they are with no holds barred in Table 1.

|

Lift method |

When to use |

When not to use |

|

ESP |

|

|

|

High pressure gaslift |

|

|

|

Conventional gaslift |

|

|

|

Plunger |

|

|

|

Rod pump |

|

|

Table 1 - Lift method selection guidelines

Gaslift—Still a Valuable Option

For gaslift, there is a solution that circumvents a lot of the issues associated with conventional gaslift - high pressure gaslift. This solution has no unloading valves and a single orifice. An expert on the topic and valued friend Branden Pronk has written a great paper, that is well worth a read. This solution can achieve rates of up to 8500 bfpd with 4000 psi injection pressure, injecting down the tubing and producing up the casing x tubing annulus.

I first worked with ESPs in 1988 on the Montrose platform in the North Sea and it is a technology that I think is superb. However, I believe high pressure gaslift is a viable alternative for high rates (above 1000 bfpd). Below 1000 bfpd, conventional gaslift would be my choice, switching to plunger as rates decline.

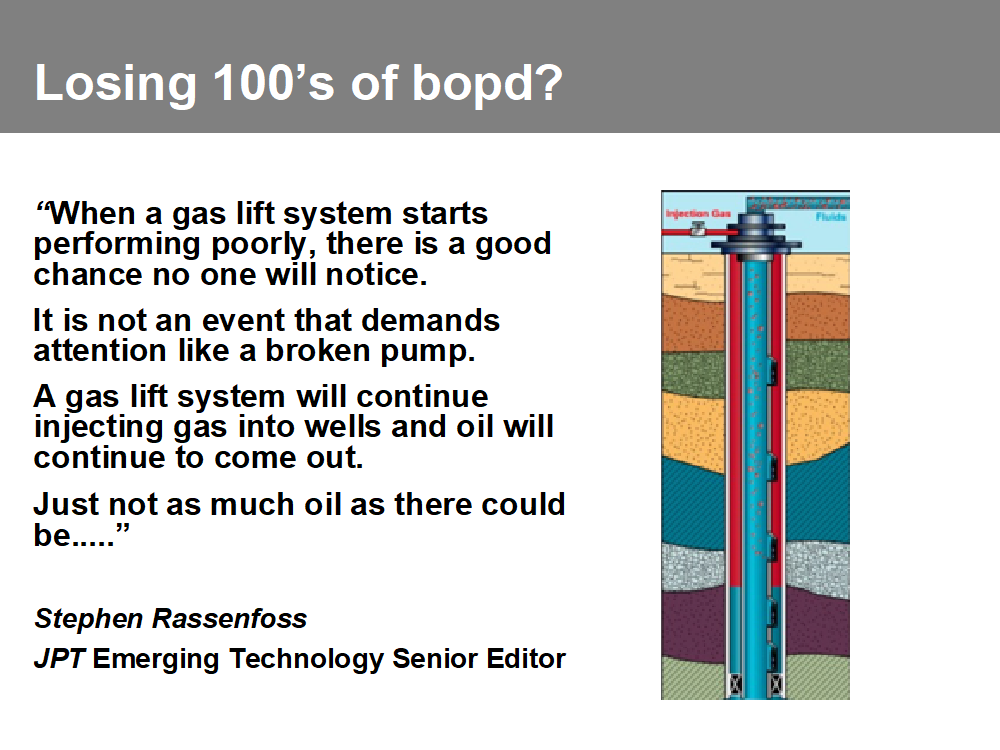

Whether using ESPs or gaslift, the challenge is to ensure that the lift method is working properly. Both methods can be subject to problems that result in less production as shown in Table 2 or Figure 3.

|

ESP |

Gaslift |

|

|

Table 2 - ESP and Gaslift problems

Figure 3 - Why gaslift can lose production

Gaslift-Specific Solutions

One of the issues I see frequently with gaslift, is that multiple valves are installed (12-15 not uncommon) with very little diligence around design and correct downhole temperature prediction. The consequence is that valves stay open, when they should be closed, resulting in reduced drawdown and less production. While the system has not failed ‘catastrophically’, production is being lost. Having a downhole pressure sensor or running periodic gradient surveys is one way to diagnose such issues and is a best practice for gaslifted wells.

The Pump Checker® Methodology

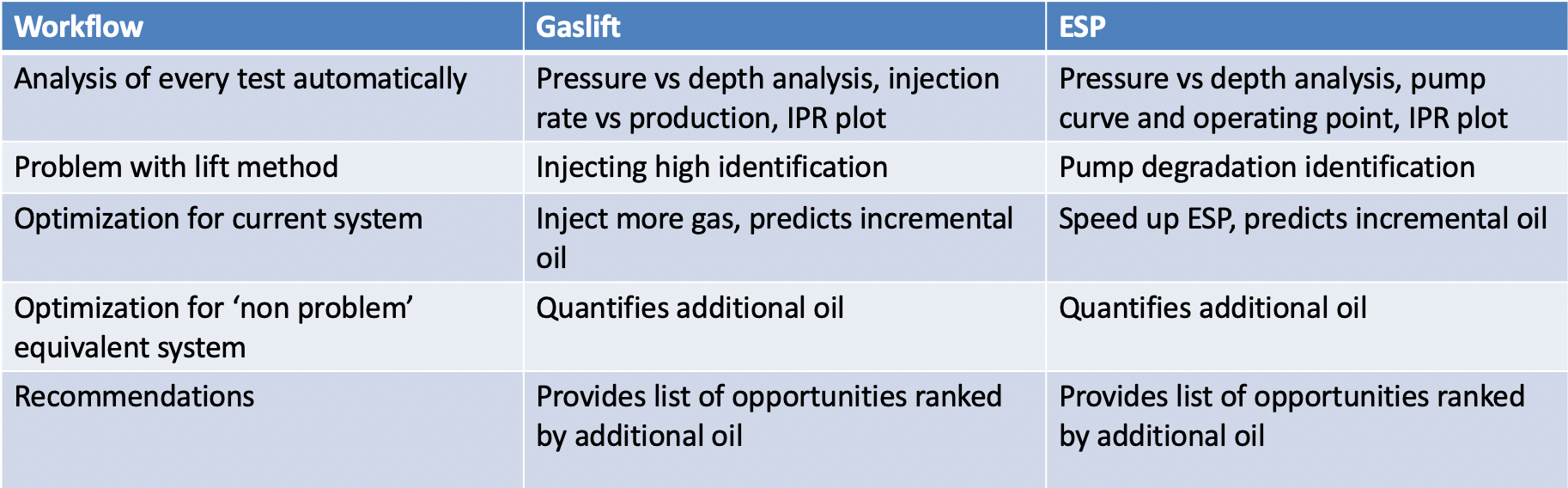

Regardless of your lift method, you need a methodology that ensures that the lift method is working effectively and giving you appropriate drawdown on your well. That is exactly what our Pump Checker software does for ESP and gaslift wells. We have a proprietary methodology that integrates physics-based models with powerful analytics to automatically analyze your wells every production test and flag problems and opportunities using our workflows as per Table 3.

Table 3 - Pump Checker workflows for ESP and gaslift

Efficiency in Manpower with Pump Checker®

In working with our clients, it’s staggering how many engineers spend much of their time on reporting, invoice processing, administration, meetings and of course the dreaded email monster – in other words very little in production optimization or problem solving. This is where a system such as Pump Checker has a benefit as it:

- Automatically identifies problems and opportunities

- Saves engineers time

- Allows focus on problem solving

- Ensures that the lift system is optimized for the well capability

- Identifies problem wells

- Identifies opportunities for additional production

- Validates well inflow performance for new designs

In summary, selecting the correct lift method is half the battle, you then need to get it to work properly. As Bill Gates once said:

Please contact us if you think our technology solution could help you managed your ESP and gaslift wells more effectively.

Artificial lift analytics: more oil, fewer failures and lower costs

.jpg?width=2097&height=770&name=ALP%20logo%20%26%20strapline%20-%20RGB%20(US%20version).jpg)