For decades we’ve had the boom and bust in our industry, that goes with the ebb and flow of the price of oil. Yikes, we’re in another crisis!

The drilling and production of unconventional wells, the availability of funding, longer laterals and bigger frac jobs has resulted in North American operators chasing production with the drill bit, at $10 million dollars per well. That’s great in a greater than $45/barrel cost environment.

As Warren Buffet says ‘It’s only when the tide goes out that you learn who has been swimming naked’.

We are currently in such a moment in our industry. How can we learn from this?

In this environment, operators need to find ways to squeeze efficiency from their existing wells, rather than drill new wells. While cutting costs is important, ultimately what is required is lowest cost per barrel. This requires a combination of production optimization and prudent reduction of total cost of operation. “Lean production operations” need to become key.

A recent article in Hart Energy focused on the transformation many oilfield producers are looking at to improve their production and maximize and adjust to the new industry economy. Shifting their eyes to maximizing economic value and reviewing the productivity of existing assets is key.

Leadership teams need to revisit capital allocation and understand that in this environment, only the lowest total cost of operation operators will survive. This requires operators to re-evaluate their organizational functions, their digital solutions and what their value producing organization should do (production engineers need to be production-focused - not administrative).

The New Oilfield Industry Focus

With the shift away from sheer number of barrels produced and toward lean production, operators are looking to make decisions based on economic efficiency or lowest total cost of operation. Without the endless rush to get new wells online, it’s time to nurture our ability to optimize the existing production base. Key questions are:

- Which wells can give more production?

- Which wells are offline (and why)?

- Which wells have sub-performing artificial lift (AL) relative to well performance?

- Is our existing well producing optimally with the existing AL equipment?

- How can this well give us more and what does it cost to obtain it?

- What is the risk of trying to get more?

- What new methods do we try that would add value to our operation?

- If something isn’t efficient, can we reallocate the money elsewhere?

- What suggestions do our team members have to address lowest total cost of operation?

Defining Your Transformation

The former CEO of Oxy (Stephen Chazen), once said on an investor call (and I’m paraphrasing), that production people could only do one of two things: (1) chase production or (2) lower costs. I disagree, if you have a clear metric that you want to achieve, it can be done.

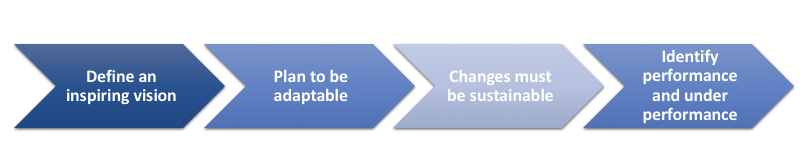

Define an inspiring vision.

Determine what your organization wants to achieve, making sure the targets are measurable and will pack some financial punch for your company. The key here is “inspiring” and making your targets specific and measurable at all levels of your organization.

Plan to be adaptable.

Develop a plan that acknowledges urgency, making key changes a priority, but without destroying everything you have built so far.

Any change must be sustainable.

Take the time to experiment with new ideas and test their contribution to success. You may be spending the same amount and gaining value.

Identify performance and under performance: Assets, teams, processes.

The goal is to improve performance and efficiency, so you must focus your efforts on getting results. Diagnose any problems quickly and stop the bleeding. Identify performance and amplify!

Take Advantage of the Value

When you capture some of gains early on, you can build and maintain momentum, building confidence in your team that the transformation is working. Each step in the right direction—each value-adding opportunity identified—increases confidence that you are on the right track. Keep score across your organization.

Artificial Lift Performance (ALP) and Pump Checker®—a Tool for Transformation

ALP’s Pump Checker solution provides an expert solution that integrates data from multiple data sources and identifies opportunities and issues through management by exception processes.

Artificial lift systems are a common area to find losses: oil, run time, and revenue. Using software to not only collect the right data, but to be able to use that data to optimize your production, down to the individual well, can provide your team with opportunities to increase production and maximize efficiency. Understanding where losses are occurring, methods to improve the efficiency, and training your team to manage the entire process gives your organization a new outlook on production—and the transformation you are looking for!

Although the idea of a transformation may be intimidating, your company’s long-term viability may depend on your ability to re-evaluate your productivity and economic health. Approaching this challenge with both asset and organization improvements in mind, you are ready to take advantage of the industry downturn to re-invent a lean and tech-savvy company.

Find out how the Pump Checker can offer you the analytics to improve your decision-making process and save you oil and money.

.jpg?width=2097&height=770&name=ALP%20logo%20%26%20strapline%20-%20RGB%20(US%20version).jpg)